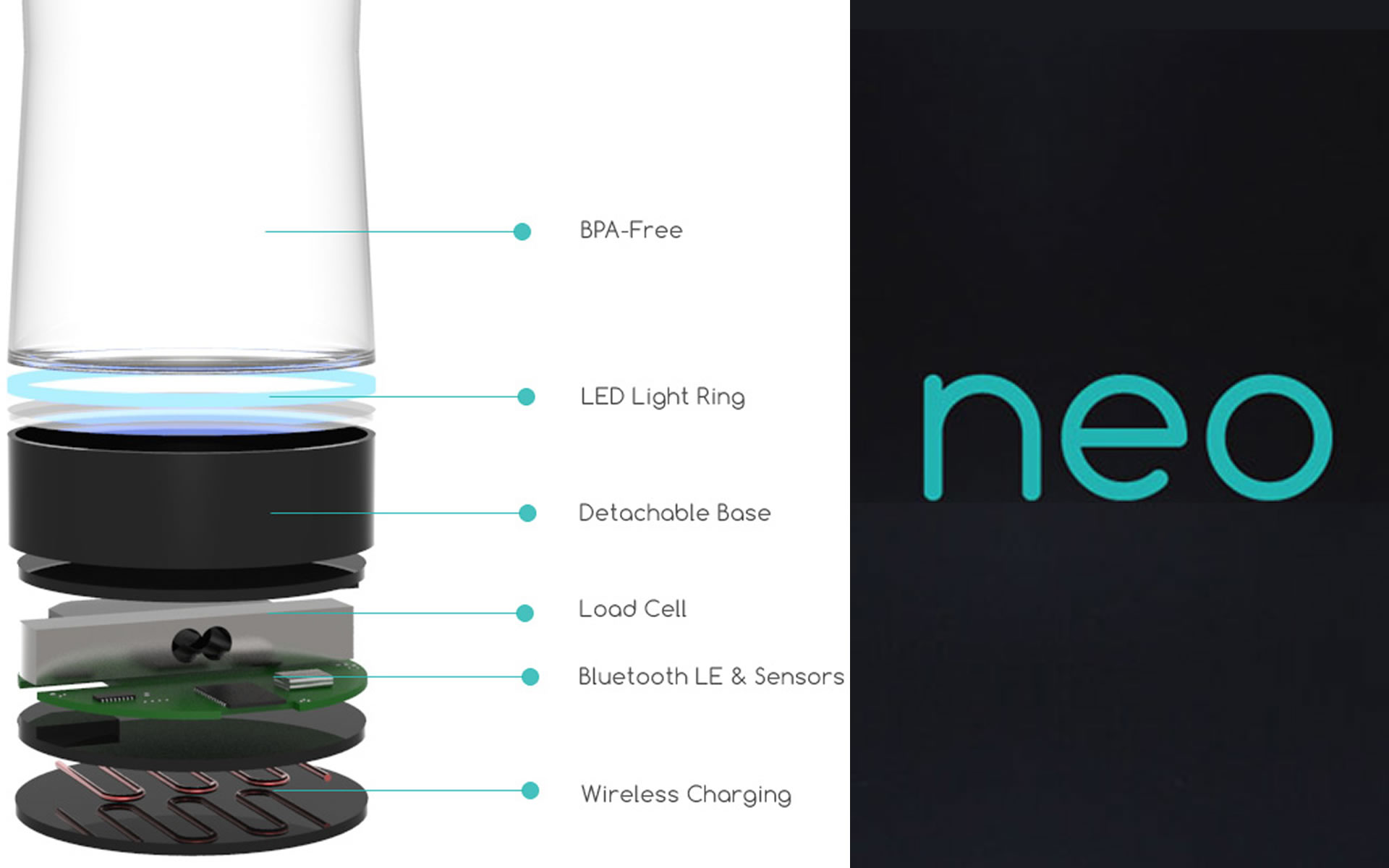

A smart jar that tracks the weight of its contents to suggest recipes and provide zero touch smart shopping experience.

- SKE Labs, Canada

Scope of work: R&D on developing a wireless weight sensor, Accuracy improvement techniques to detect variation as small as 1gm, low power system with deep sleep mode for longer standby time, interaction with Android app to broadcast data in real time, design and develop hardware and software for the system, design and develop 3D casing for the unit.Wireless weight sensors are very common with systems that calculate upto 5Kg (mini scales) to higher values. The major problem with these devices is in is accuracy which is normally around 5gm-10gm with a tolerance level of +-2gm and large form factor. This project required us to rethink on a design that is low power, very small in form factor, max load capacity of 5Kg and has an accuracy of 1gm with a tolerance level of +-.5gm.

Our team started with the most crucial weight sensor part. A suitable 5Kg weight sensor was obtained which measured under 5.5cm in length and under 1.5 cm in breadth and height. It was then interfaced with a 24 bit ADC and preamp stages to obtain even the slightest of variations. The data obtained from the sensor was then pushed into an 8 bit microcontroller and BLE module. The BLE interface is used to transmit the calculated weight values on to a connected Android or iOS app. Initial readings were completely shadowed by the high amount of fluctuations and value jumps. To avoid this and obtain the actual data, a good amount of work was put into building an error correcting algorithm. This helped bring down the measurement accuracy to 2gm. We still had to push further to get the required specifications and started working on both the hardware and software end. After a few final tweaks in the outer body design and assembly, we were able to achieve an accuracy of .5gm and chose to use the 1gm accuracy setting. This also enabled us to have a tolerance level as small as .1-.2gm.

The entire casing for initial prototypes were designed in 2 D and later cut out of sheets with the help of CNC laser cutters. The round edges was particularly challenging to be built but careful implementation of lattice hinges made it possible to bend a rigid surface and create a closed round figure.

The product was later unveiled in Las Vegas at CES 2015 and then featured in various major media including Forbes, CNN and Huffington post.